Blog

Boos Production Efficiency with High End CNC Cutting Machines

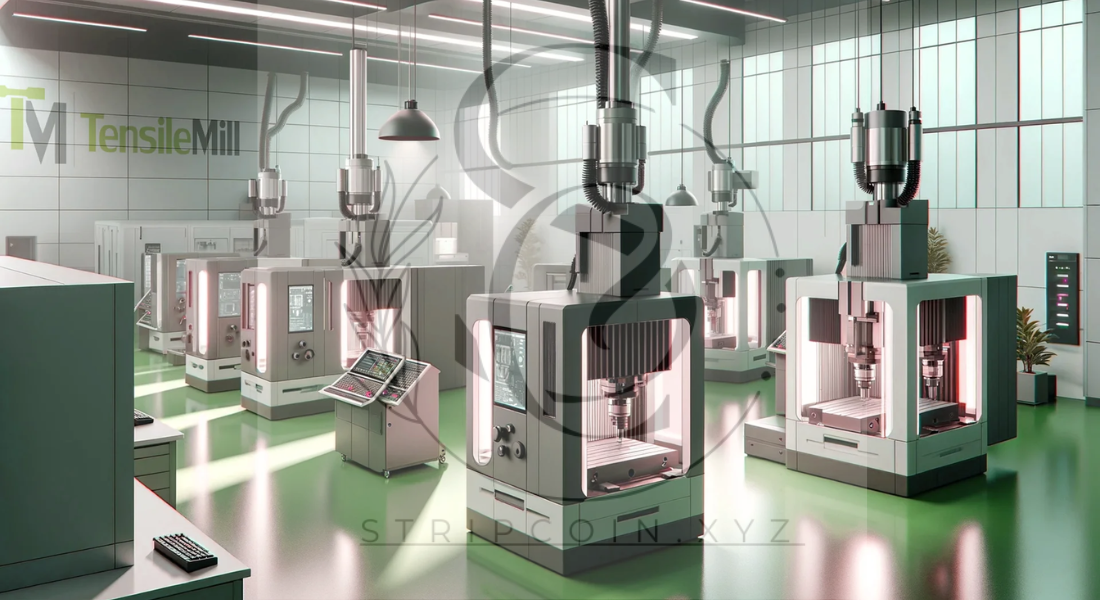

Modern manufacturing demands precision, speed, and versatility. High end CNC cutting machines for production deliver unparalleled performance, ensuring manufacturers achieve consistent results across diverse materials. These advanced machines represent the cutting edge of production technology, combining accuracy with automation for maximum efficiency.

Advanced Precision with High End CNC Cutting Machines

High end CNC cutting machines for production excel in precision, offering micro-level accuracy that ensures flawless output. Whether cutting metals, plastics, or composites, these machines produce clean, intricate designs that meet exact specifications.

By leveraging computer-controlled technology, these machines minimize human error, reducing waste and ensuring consistent quality. This precision is critical for industries like aerospace, automotive, and electronics, where even minor deviations can impact performance.

Versatility Across Diverse Materials

High end CNC cutting machines for production adapt effortlessly to various materials, making them indispensable for modern manufacturing. From aluminum and steel to wood and acrylic, these machines handle everything with ease.

Different cutting tools and techniques, such as plasma, laser, or waterjet cutting, expand the capabilities of CNC machines. Manufacturers can switch between materials seamlessly, enhancing production flexibility and catering to a broader range of applications.

Speed and Automation for Higher Productivity

Efficiency is a hallmark of high end CNC cutting machines for production. These machines operate at high speeds while maintaining exceptional precision, reducing production times without compromising quality.

Automation further enhances productivity, allowing manufacturers to schedule tasks, monitor progress, and optimize workflows. With features like automatic tool changing and real-time diagnostics, CNC machines streamline operations, helping businesses meet tight deadlines with ease.

Cost Efficiency with Reduced Waste

Investing in high end CNC cutting machines for production leads to significant cost savings over time. Their precision reduces material waste, while automation minimizes labor costs by enabling continuous, unattended operation.

These machines also enhance tool lifespan by optimizing cutting speeds and techniques, reducing wear and tear. For manufacturers, these savings translate into higher profitability and a faster return on investment.

User-Friendly Interfaces for Seamless Operation

High end CNC cutting machines for production feature intuitive interfaces that simplify programming and operation. Modern CNC systems often include touchscreens, 3D simulation tools, and user-friendly software, making them accessible even to operators with minimal training.

Real-time feedback and error detection ensure smooth operation, allowing users to address issues before they affect production. This ease of use makes CNC machines a practical choice for both small businesses and large-scale manufacturers.

Customization Capabilities for Tailored Production

Customization is essential for meeting diverse production needs, and high end CNC cutting machines for production deliver unmatched versatility. From creating complex prototypes to mass-producing components, these machines adapt to specific requirements.

With CAD/CAM integration, manufacturers can design and produce intricate parts with ease. This capability enables businesses to offer tailored solutions to clients, enhancing customer satisfaction and expanding market opportunities.

Durability and Reliability for Long-Term Performance

Durability is a critical factor for production equipment, and high end CNC cutting machines for production are built to last. Constructed from high-quality materials and featuring robust components, these machines withstand the rigors of continuous operation.

Routine maintenance ensures long-term reliability, minimizing downtime and maximizing productivity. Manufacturers who prioritize durability benefit from consistent performance and reduced equipment replacement costs.

Integration with Smart Manufacturing

Smart manufacturing is the future, and high end CNC cutting machines for production play a central role in this evolution. These machines integrate seamlessly with IoT systems, enabling real-time monitoring, predictive maintenance, and data-driven decision-making.

By connecting CNC machines to centralized networks, manufacturers gain insights into operational efficiency, energy consumption, and production trends. This connectivity enhances overall performance, driving innovation and competitiveness in a rapidly evolving market.

Sustainability with Eco-Friendly Technology

Sustainability is a growing concern, and high end CNC cutting machines for production address this with eco-friendly features. From energy-efficient motors to waste reduction technologies, these machines help manufacturers minimize their environmental impact.

Advanced cutting techniques, such as waterjet cutting with recycled water, further enhance sustainability. Businesses that adopt green practices not only contribute to environmental preservation but also appeal to eco-conscious clients and partners.

Industries Benefiting from High End CNC Cutting Machines

High end CNC cutting machines for production are transforming multiple industries, including:

- Aerospace: Precise components for aircraft and spacecraft.

- Automotive: Complex parts for engines and chassis.

- Electronics: Intricate circuits and housings for devices.

- Construction: Custom panels and frameworks.

- Furniture: Detailed woodwork and metal designs.

These machines provide the versatility and performance needed to meet the demands of specialized industries.

Tips for Choosing the Right CNC Cutting Machine

When selecting high end CNC cutting machines for production, consider these factors:

- Material Compatibility: Ensure the machine can handle the materials you work with.

- Cutting Technique: Choose between laser, plasma, or waterjet cutting based on your needs.

- Automation Features: Look for features like tool changers and real-time diagnostics.

- Software Integration: Ensure compatibility with your existing CAD/CAM systems.

- Support and Maintenance: Opt for manufacturers with excellent after-sales support.

Making the right choice ensures your investment aligns with your production goals.

Maintenance Tips for Maximizing Machine Performance

To keep high end CNC cutting machines for production operating at peak efficiency, follow these maintenance tips:

- Regular Cleaning: Remove debris and lubricate moving parts to prevent wear.

- Inspect Components: Check for signs of wear and replace damaged parts promptly.

- Software Updates: Keep control systems and software up to date for optimal performance.

- Calibrate Regularly: Ensure cutting accuracy with routine calibration.

- Train Operators: Provide training to reduce errors and prolong machine lifespan.

Consistent maintenance maximizes productivity and extends the machine’s lifespan.

Why Invest in High End CNC Cutting Machines

High end CNC cutting machines for production offer unparalleled advantages, from precision and speed to cost efficiency and sustainability. They empower manufacturers to meet evolving market demands while maintaining high standards of quality.

For businesses aiming to stay competitive, investing in CNC machines is a strategic move. These machines not only enhance production capabilities but also open doors to new opportunities and markets.

The Future of CNC Cutting Technology

As technology advances, high end CNC cutting machines for production will continue to evolve. Innovations such as AI integration, advanced robotics, and enhanced material compatibility promise even greater efficiency and versatility.

The future of manufacturing lies in intelligent, automated systems that adapt to dynamic demands. By adopting cutting-edge CNC technology, businesses can position themselves at the forefront of this transformation.

Maximize Efficiency with High End CNC Cutting Machines

High end CNC cutting machines for production are more than tools—they are the backbone of modern manufacturing. With their unmatched precision, speed, and versatility, these machines redefine what’s possible in production.

Investing in CNC technology ensures your business remains competitive, efficient, and ready to tackle the challenges of tomorrow. Choose the right CNC cutting machine today and take your production capabilities to new heights.