Blog

High End Lathe Machines for Precision Revolutionizing Modern Manufacturing

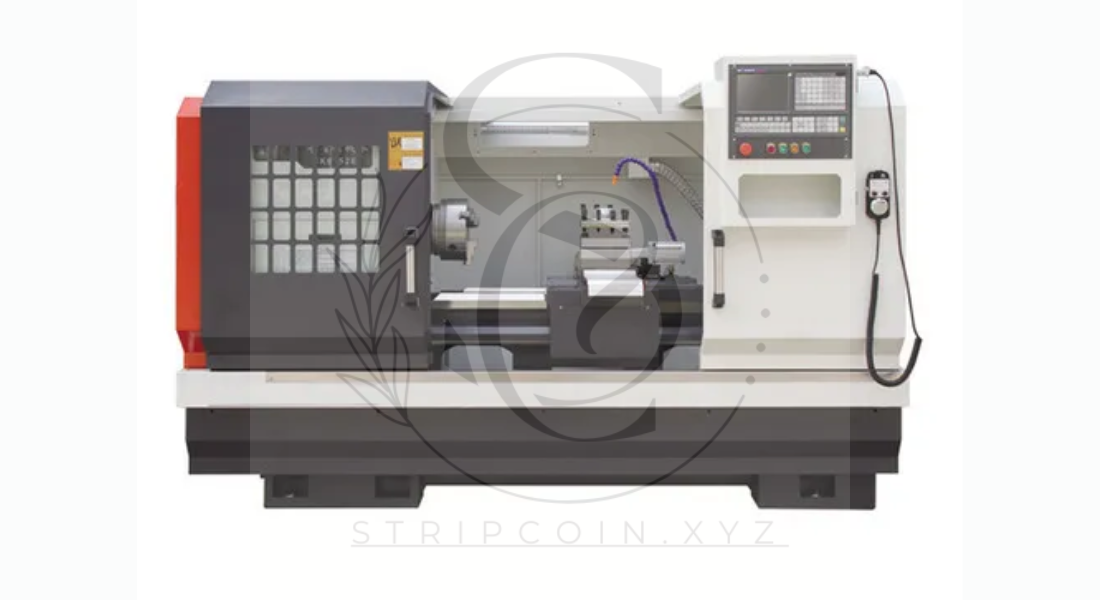

In modern manufacturing, precision isn’t optional—it’s essential. High-end lathe machines for precision play a pivotal role in creating components that meet exact specifications. These advanced machines combine state-of-the-art technology with robust engineering, ensuring industries achieve unparalleled accuracy in production.

Why Precision Is Vital in Today’s Manufacturing

Precision machining has transformed the way industries approach production. High-end lathe machines for precision deliver consistent quality, reduce errors, and optimize material usage. From aerospace and automotive to medical equipment manufacturing, these machines enable businesses to meet strict standards and exceed customer expectations.

Advanced Features That Set High-End Machines Apart

High-end lathe machines come equipped with features that redefine efficiency and accuracy. Digital interfaces, automated tool changers, and CNC programming allow for faster setups and more precise operations. These advancements not only save time but also improve overall output quality.

Boosting Productivity with Cutting-Edge Tools

Productivity is at the heart of every successful manufacturing operation. High-end lathe machines for precision streamline workflows by performing complex tasks with minimal human intervention. Their high-speed spindles and advanced cooling systems ensure optimal performance, even during extended production cycles.

Creating Complex Components with Ease

Modern industries demand intricate designs and flawless components. High-end lathe machines excel in crafting complex geometries and meeting tight tolerances. From surgical instruments to aerospace parts, these machines handle intricate projects with unmatched accuracy.

Durable Construction for Reliable Performance

High-end lathe machines are built to endure heavy-duty use. Their robust construction ensures long-term reliability, even in high-pressure environments. Precision-machined components and corrosion-resistant materials guarantee consistent performance over years of operation.

User-Friendly Interfaces for Seamless Operation

Despite their advanced capabilities, these machines are designed for ease of use. High-end lathe machines for precision feature intuitive controls, touchscreen interfaces, and customizable settings. This simplicity ensures operators can quickly master the machine’s functions, improving productivity and reducing training time.

How Automation Enhances Manufacturing Efficiency

Automation is revolutionizing manufacturing, and high-end lathe machines integrate seamlessly with automated systems. Robotic arms, automated feeders, and IoT connectivity allow businesses to scale operations while maintaining precision. These features reduce downtime and ensure consistent output.

Achieving Speed and Precision Simultaneously

Speed and precision are often seen as opposing forces, but high-end lathe machines strike the perfect balance. Their advanced motor systems and optimized cutting tools deliver rapid results without compromising accuracy, enabling industries to meet tight deadlines.

Reducing Material Waste with Precision Machining

Material waste can significantly impact profitability. High-end lathe machines for precision minimize waste by delivering exact cuts and reducing errors. This efficiency not only lowers costs but also supports sustainable manufacturing practices by conserving resources.

Customizable Features for Versatile Applications

Manufacturers often require tailored solutions, and these machines deliver. High-end lathe machines offer customizable options, including adjustable cutting speeds, tool configurations, and programmable workflows. This adaptability makes them suitable for a wide range of industries and projects.

Perfect for Prototyping and Mass Production

High-end lathe machines for precision cater to both small-scale prototyping and large-scale manufacturing. Their versatility allows businesses to create prototypes with intricate details or produce thousands of identical parts with consistent quality, ensuring they meet diverse production needs.

Superior Cutting Tools That Maximize Performance

The cutting tools used in these machines are crafted from premium materials like carbide and ceramic. These tools maintain sharpness and durability, enabling the machining of challenging materials such as titanium and hardened steel while ensuring consistent results.

Seamless Integration with CAD/CAM Software

Digital design and manufacturing go hand in hand, and high-end lathe machines integrate seamlessly with CAD/CAM software. This compatibility simplifies programming, enhances accuracy, and ensures smooth transitions from design to production.

Compact Designs for Efficient Workspaces

Space constraints are common in manufacturing facilities, but high-end lathe machines address this challenge with compact designs. Despite their smaller footprint, these machines deliver powerful performance, making them ideal for both small workshops and large industrial setups.

Minimizing Downtime with Reliable Machines

Unexpected downtime can disrupt production schedules and increase costs. High-end lathe machines for precision are engineered for reliability, featuring preventative maintenance alerts and self-diagnostic systems that reduce the likelihood of breakdowns and ensure consistent operations.

Prototyping Made Easy with Precision Tools

Prototyping requires precision and flexibility, and these machines excel at both. High-end lathes enable manufacturers to create prototypes with exact specifications, helping businesses refine their designs and accelerate the product development process.

Energy Efficiency for Sustainable Manufacturing

Energy efficiency is a growing priority for industries aiming to reduce operational costs and environmental impact. High-end lathe machines incorporate energy-saving technologies, consuming less power while maintaining superior performance, making them an eco-friendly choice.

How Precision Drives Industry Standards

Meeting and exceeding industry standards is crucial for staying competitive. High-end lathe machines for precision empower manufacturers to produce flawless components that set new benchmarks for quality, ensuring products are reliable, durable, and consistent.

Supporting Innovation Across Industries

Innovation relies on tools that can handle complex challenges. High-end lathe machines enable industries to experiment with new materials, designs, and manufacturing techniques, fostering creativity and driving progress in fields like aerospace, robotics, and renewable energy.

Perfect for Global Manufacturing Markets

The global demand for precision is higher than ever, and these machines cater to diverse manufacturing needs worldwide. High-end lathe machines for precision deliver consistent quality, ensuring businesses meet international standards and maintain a competitive edge.

Precision That Enhances Customer Satisfaction

Flawless components lead to high-quality products, which in turn drive customer satisfaction. High-end lathe machines ensure every part meets exact specifications, reducing returns and fostering trust in your brand.

Investing in Long-Term Success

High-end lathe machines are more than a purchase—they’re an investment in a company’s future. These machines improve efficiency, reduce waste, and enhance quality, providing long-term value and positioning businesses for success in a competitive marketplace.

Why Every Manufacturer Needs Precision Lathes

Manufacturers across industries recognize the value of high-end lathe machines for precision. Their versatility, reliability, and advanced features make them indispensable tools for achieving excellence, whether in prototyping, small-batch production, or mass manufacturing.

Conclusion: The Precision Revolution in Manufacturing

High-end lathe machines for precision are transforming the manufacturing landscape. By combining speed, accuracy, and advanced technology, they empower industries to produce flawless components and meet the highest standards of quality. Investing in these cutting-edge machines ensures businesses stay ahead in today’s fast-paced, competitive world.