Blog

High Tech Industrial Automation Tools Revolutionizing Modern Manufacturing

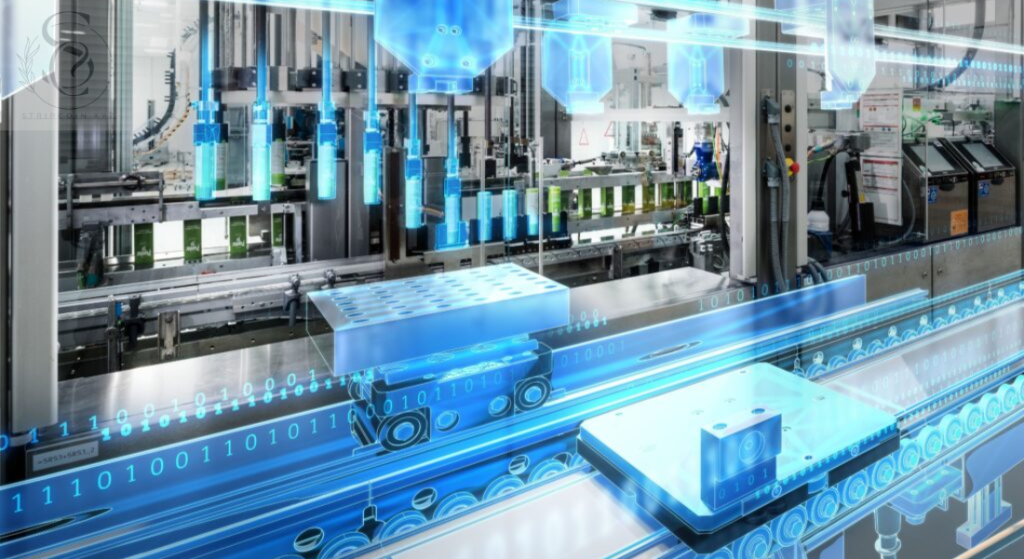

In the rapidly evolving world of manufacturing, high tech industrial automation tools are driving efficiency, precision, and innovation. These tools transform traditional processes, reduce human error, and enhance productivity across industries. With their ability to automate complex tasks, they’re setting new standards for quality and operational excellence. Dive into the benefits, applications, and future of these cutting-edge technologies.

Streamlined Operations with Advanced Robotics

Robotics lies at the heart of modern industrial automation. High-tech robots excel in performing repetitive and intricate tasks with unmatched accuracy. From assembling products on production lines to handling hazardous materials, robotics improves speed and safety.

Industries benefit from reduced labor costs and faster cycle times, while employees can focus on creative and strategic tasks. The integration of robotics into manufacturing workflows has redefined what’s possible in terms of output and reliability.

Precision Engineering with CNC Machines

Computer Numerical Control (CNC) machines are essential tools for precision manufacturing. These automated systems cut, shape, and form materials with micrometer-level accuracy, ensuring consistency in every piece produced.

High tech CNC machines support a wide range of industries, from aerospace to automotive, delivering components that meet exacting standards. Their ability to operate continuously with minimal downtime maximizes efficiency and guarantees superior quality.

Real-Time Monitoring with IoT Integration

The Internet of Things (IoT) enhances industrial automation by connecting machines, sensors, and systems. IoT-enabled tools provide real-time data on machine performance, production rates, and potential issues. This connectivity allows manufacturers to make informed decisions quickly.

Real-time monitoring improves predictive maintenance, reducing unexpected downtime and enhancing overall efficiency. IoT integration is a cornerstone of the smart factory revolution, where every process is optimized for peak performance.

Enhanced Efficiency with AI and Machine Learning

Artificial intelligence (AI) and machine learning algorithms empower high tech industrial automation tools to adapt and improve over time. These technologies analyze vast amounts of data to identify patterns, optimize workflows, and predict maintenance needs.

AI-driven automation tools bring a level of intelligence to manufacturing processes, allowing for faster decision-making and continuous improvement. Industries leveraging AI gain a competitive edge through smarter, more efficient operations.

Safety First with Automated Monitoring Systems

Ensuring worker safety is a top priority in industrial environments. Automated monitoring systems equipped with high tech sensors detect potential hazards, such as equipment malfunctions or environmental risks, in real time.

These tools provide instant alerts, enabling swift corrective action to prevent accidents. By enhancing workplace safety, automation tools protect employees and reduce downtime caused by safety incidents.

Energy Efficiency with Smart Automation

Energy efficiency is a growing concern in modern industries, and automation tools play a key role in addressing it. High tech tools monitor and optimize energy usage, reducing waste and lowering operational costs.

Smart energy management systems track consumption patterns, allowing industries to implement sustainable practices. This not only benefits the environment but also improves profitability by minimizing resource wastage.

Custom Solutions with Modular Systems

Modular automation tools offer unparalleled flexibility, allowing industries to customize systems based on specific needs. These tools can be scaled up or down, reconfigured, and adapted to evolving production requirements.

This modularity ensures that businesses can respond quickly to market changes, maintain high levels of efficiency, and reduce downtime during transitions. High tech modular systems represent the future of adaptable and dynamic manufacturing.

Precision Control with Advanced Sensors

High tech sensors are integral to industrial automation, providing accurate measurements and feedback. From detecting temperature fluctuations to monitoring pressure levels, sensors ensure processes remain within optimal parameters.

The data collected by these sensors enhances quality control, allowing manufacturers to identify and rectify issues before they affect production. This precision leads to consistent product quality and increased customer satisfaction.

Faster Production with Automated Assembly Lines

Automated assembly lines powered by advanced tools significantly speed up production processes. These lines minimize manual intervention, ensuring consistent output and reducing errors.

High tech automation tools streamline the assembly of complex products, from electronics to heavy machinery. The result is faster time-to-market and the ability to meet growing consumer demands efficiently.

Data-Driven Decision Making with Analytics

Industrial automation tools generate vast amounts of data, which can be harnessed through advanced analytics. These insights help businesses identify bottlenecks, predict trends, and optimize operations.

Data-driven decision-making improves productivity and allows industries to stay ahead in competitive markets. By leveraging analytics, businesses transform raw data into actionable strategies for growth and innovation.

Predictive Maintenance for Maximum Uptime

Downtime can be costly, and predictive maintenance tools ensure it’s minimized. High tech industrial automation tools equipped with AI and IoT monitor equipment health and predict potential failures before they occur.

This proactive approach reduces maintenance costs, prevents unexpected disruptions, and extends the lifespan of machinery. Industries enjoy uninterrupted operations and enhanced efficiency with predictive maintenance systems.

Collaborative Robots for Human-Machine Synergy

Collaborative robots, or cobots, work alongside humans to enhance productivity and safety. These robots handle repetitive or strenuous tasks while allowing workers to focus on more complex responsibilities.

High tech cobots are equipped with sensors and AI to interact safely with humans, making them an integral part of modern industrial automation. Their versatility and adaptability enable seamless integration into diverse manufacturing processes.

Improved Quality Assurance with Automated Inspections

Quality assurance is vital in maintaining product standards, and automation tools excel in this area. High tech inspection systems use vision technology, lasers, and sensors to detect defects with precision.

Automated inspections ensure that only flawless products leave the production line, reducing waste and enhancing customer trust. These tools set new benchmarks for quality control in manufacturing.

Why High Tech Industrial Automation Tools Matter

High tech industrial automation tools transform manufacturing by delivering precision, efficiency, and innovation. They reduce operational costs, improve product quality, and enhance workplace safety. From AI-powered systems to IoT-enabled machines, these tools represent the cutting edge of industrial technology.

Investing in automation tools allows businesses to stay competitive in a fast-paced market. By embracing these technologies, industries unlock new levels of productivity and innovation.

Conclusion: The Future of Smart Manufacturing

Industrial automation is no longer a luxury—it’s a necessity for businesses aiming to thrive in the modern era. High tech industrial automation tools empower industries to operate smarter, safer, and more efficiently. As technology continues to advance, these tools will play an even greater role in shaping the future of manufacturing.

Adopt high tech automation tools today and experience the transformation they bring to your operations. From streamlining processes to enhancing safety, these tools are the key to staying ahead in a rapidly changing world.