Blog

Luxury Precision Milling Machines: Redefining Craftsmanship and Efficiency

Luxury precision milling machines are the epitome of advanced manufacturing technology, offering unparalleled accuracy, efficiency, and versatility. These state-of-the-art machines have become a cornerstone in industries requiring intricate detailing and high-quality production, including aerospace, automotive, and luxury goods. If precision and reliability are your priorities, investing in a luxury precision milling machine is a decision that guarantees superior results.

What Are Luxury Precision Milling Machines?

Luxury precision milling machines are high-performance equipment designed to shape, cut, and finish materials with extraordinary accuracy. Unlike standard milling machines, these luxury models incorporate advanced features, innovative technologies, and premium materials to deliver exceptional results.

- How They Work

Using rotating cutting tools, milling machines remove material from a workpiece to create precise shapes and dimensions. Luxury models are equipped with sophisticated control systems and sensors, ensuring consistent performance. - What Makes Them “Luxury”?

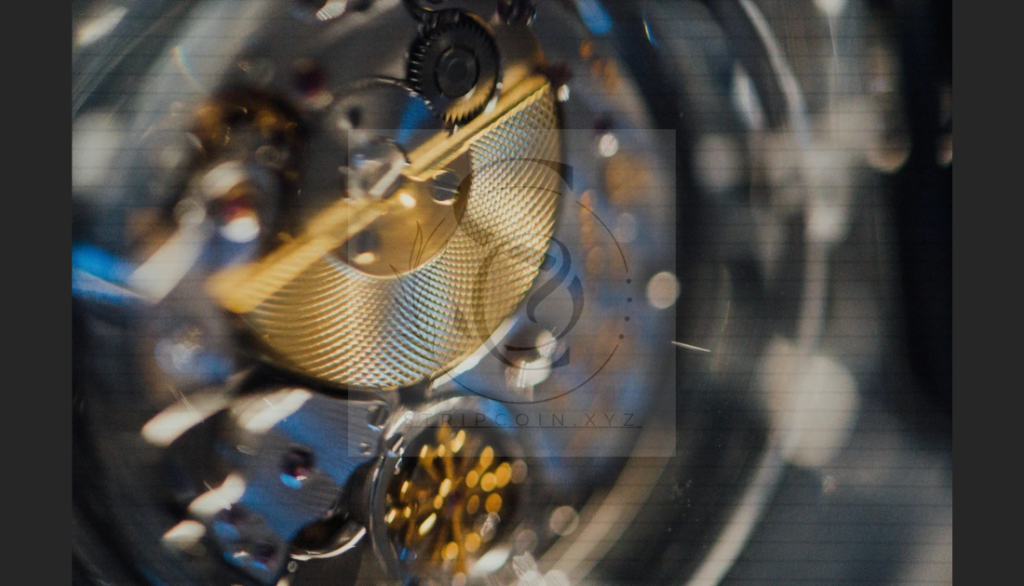

These machines stand out due to their superior craftsmanship, advanced automation, and user-friendly interfaces. They are designed for professionals who demand perfection in every detail. - Applications

Luxury precision milling machines are widely used in industries like jewelry making, watch manufacturing, medical device production, and custom automotive parts.

Key Features of Luxury Precision Milling Machines

Understanding the features of luxury precision milling machines helps you appreciate their capabilities and make an informed choice. These features set them apart from conventional options.

- Advanced CNC Controls

Computer numerical control (CNC) systems enable precise programming of cutting operations. This ensures consistent results and allows for intricate designs. - High-Quality Build Materials

Luxury models are often made from premium materials like stainless steel and titanium, ensuring durability and stability during high-speed operations. - Micron-Level Accuracy

These machines deliver exceptional precision, often achieving tolerances within a few microns. This level of accuracy is crucial for applications requiring flawless results. - Multi-Axis Capability

Many luxury milling machines support 5-axis or even 7-axis operations, enabling complex geometries and reducing the need for multiple setups. - Automated Tool Changers

Integrated tool changers streamline the manufacturing process by automatically switching between cutting tools, saving time and enhancing efficiency. - Integrated Quality Control

Built-in sensors and monitoring systems ensure real-time quality checks, minimizing errors and waste. - User-Friendly Interfaces

Touchscreen controls and intuitive software make these machines accessible to both experienced professionals and new users.

Benefits of Using Luxury Precision Milling Machines

Investing in a luxury precision milling machine offers a wide range of benefits, from improving production quality to enhancing operational efficiency. Here’s why they are worth the investment.

- Superior Product Quality

The unmatched accuracy of these machines results in flawless products. This is particularly important for industries where precision is non-negotiable. - Increased Productivity

Advanced automation and faster machining speeds allow for higher output, reducing production timelines without compromising quality. - Cost Efficiency

Although the initial investment is higher, the long-term savings on material waste, tool wear, and production errors make these machines a cost-effective choice. - Enhanced Versatility

Luxury milling machines handle a wide variety of materials, including metals, plastics, and composites. This flexibility makes them suitable for diverse applications. - Minimal Downtime

High-quality components and advanced diagnostics reduce maintenance requirements and ensure uninterrupted operation. - Improved Safety

Automated systems and protective enclosures minimize risks to operators, making these machines safer to use in demanding environments.

Choosing the Right Luxury Precision Milling Machine

Selecting the perfect milling machine requires careful consideration of your specific needs and operational requirements. Follow these steps to make the right choice.

- Assess Your Needs

Determine the type of projects you’ll be working on and the level of precision required. Consider factors like material type, design complexity, and production volume. - Evaluate Performance Specifications

Look for key performance indicators such as spindle speed, axis capabilities, and power output. Higher specifications translate to better performance. - Consider Software Compatibility

Ensure the machine’s CNC system is compatible with your preferred design software. This ensures seamless integration and efficient workflow. - Check Brand Reputation

Reputable manufacturers often provide better after-sales support, warranties, and training. Research customer reviews and industry recommendations before deciding. - Test for User-Friendliness

Opt for machines with intuitive interfaces and easy-to-navigate controls. This reduces the learning curve and increases operational efficiency. - Plan for Future Growth

If your business is expanding, choose a machine that can scale with your needs. Features like multi-axis capability and automated tool changers are essential for complex projects.

Maintaining Luxury Precision Milling Machines

Proper maintenance ensures your milling machine remains in top condition and delivers consistent performance. These tips help maximize its lifespan and efficiency.

- Clean Regularly

Remove chips, dust, and debris from the machine after every use. This prevents buildup and ensures smooth operation. - Lubricate Moving Parts

Regular lubrication reduces friction and wear on moving components. Use the manufacturer-recommended lubricants for best results. - Inspect Tools and Components

Periodically check cutting tools, spindles, and belts for signs of wear or damage. Replace worn parts promptly to avoid performance issues. - Calibrate Often

Regular calibration ensures the machine maintains its precision. Follow the manufacturer’s guidelines for calibration frequency. - Monitor Software Updates

Keep the machine’s software up to date to benefit from the latest features and security patches. - Schedule Professional Servicing

Annual servicing by certified technicians helps identify and resolve potential issues before they affect performance.

Leading Brands in Luxury Precision Milling Machines

Several manufacturers are renowned for their high-quality precision milling machines. These brands consistently deliver cutting-edge technology and exceptional reliability.

- DMG MORI

Known for their advanced CNC technology, DMG MORI offers luxury milling machines that cater to a wide range of industries. - Haas Automation

Haas produces user-friendly and efficient milling machines designed for professionals seeking reliability and innovation. - Mazak

Mazak’s machines are celebrated for their multi-tasking capabilities, enabling complex operations with ease. - Okuma

Okuma specializes in high-precision machines that provide exceptional accuracy and long-term durability. - Hermle

Hermle’s luxury milling machines are ideal for industries requiring ultra-fine precision, such as medical devices and aerospace components.

The Future of Luxury Precision Milling Machines

As technology advances, luxury precision milling machines are becoming more innovative and efficient. Several trends are shaping the future of this industry.

- Increased Automation

Machines equipped with artificial intelligence and machine learning are streamlining operations and reducing human intervention. - Eco-Friendly Designs

Manufacturers are focusing on sustainable materials and energy-efficient systems to reduce the environmental impact of machining. - Advanced Connectivity

Integration with IoT (Internet of Things) allows real-time monitoring, remote diagnostics, and predictive maintenance. - Enhanced Customization

Future machines will offer more customizable options, enabling businesses to tailor solutions to their unique needs.

Conclusion: Unlock Precision with Luxury Milling Machines

Luxury precision milling machines are a game-changer for industries demanding unparalleled accuracy and efficiency. From creating intricate designs to improving production workflows, these machines deliver results that surpass expectations. By choosing the right model, maintaining it properly, and staying updated with technological advancements, you can maximize the benefits of this high-end equipment.

Invest in a luxury precision milling machine today and experience the difference it brings to your craftsmanship and operational efficiency. With the right machine, the possibilities are limitless.