Blog

CNC Engraving Machines for Precision Revolutionizing Craftsmanship

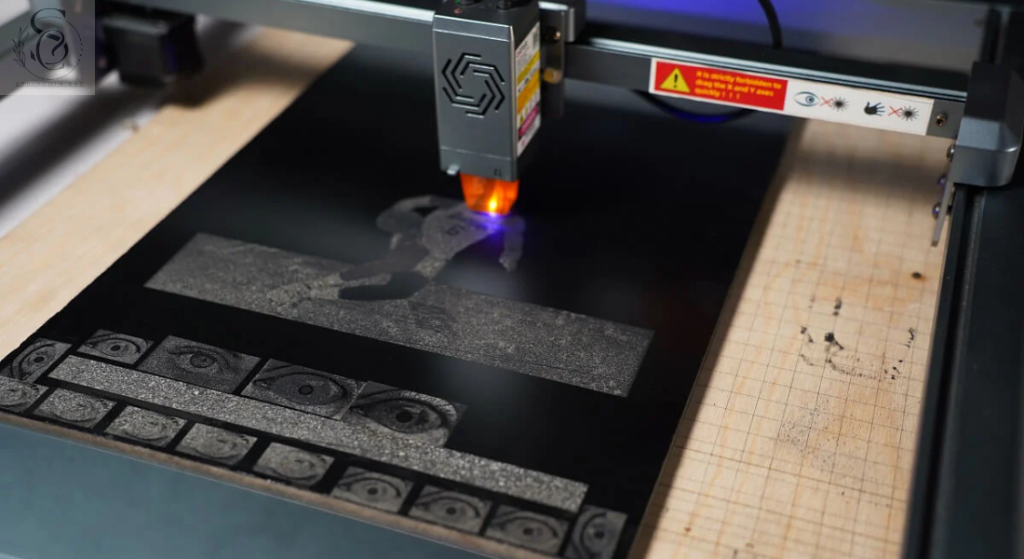

In the world of manufacturing and design, precision is the cornerstone of excellence. CNC engraving machines for precision have become the gold standard for achieving intricate designs and flawless finishes. These machines combine cutting-edge technology with unparalleled accuracy, making them indispensable for professionals and hobbyists alike. Discover how CNC engraving is transforming industries and elevating craftsmanship.

The Role of CNC Engraving in Modern Manufacturing

Precision Beyond Expectations

CNC engraving machines for precision redefine what’s possible in detailed work. They enable the creation of complex patterns and designs with micrometer-level accuracy. Whether crafting jewelry, signage, or industrial components, these machines deliver results that exceed traditional methods.

Versatility Across Industries

From aerospace to arts, CNC engraving finds applications across various fields. These machines handle diverse materials, including metals, plastics, and wood, offering versatility for projects ranging from mechanical parts to artistic masterpieces.

Speed and Efficiency

Time is money, especially in manufacturing. CNC engraving machines work with incredible speed, producing intricate designs faster than manual methods. This efficiency allows businesses to scale production without compromising quality.

Key Features of CNC Engraving Machines for Precision

Advanced Software Integration

Modern CNC engraving machines come equipped with powerful software that translates digital designs into precise engravings. This integration ensures seamless operation and the ability to replicate designs with absolute consistency.

High-Speed Spindles

The spindle is the heart of any CNC engraving machine. High-speed spindles ensure clean cuts and smooth finishes, even on tough materials. This feature is crucial for achieving the level of precision that these machines are known for.

Multi-Axis Capabilities

Many CNC engraving machines offer multi-axis functionality, allowing them to engrave complex shapes and surfaces. This capability is essential for industries that demand intricate details, such as jewelry and automotive components.

Automated Tool Changing

Switching between tools manually slows down production. Automated tool changers streamline the process, enabling seamless transitions and reducing downtime. This feature boosts productivity while maintaining accuracy.

Benefits of Using CNC Engraving Machines

Unmatched Accuracy

CNC engraving machines deliver unparalleled precision, ensuring every detail of your design is executed flawlessly. This accuracy is vital for industries where even the smallest error can compromise functionality or aesthetics.

Increased Productivity

These machines operate continuously without fatigue, producing more in less time. Their efficiency allows businesses to meet tight deadlines and high-volume demands without sacrificing quality.

Cost-Effectiveness

While the initial investment in a CNC engraving machine may be significant, the long-term savings are substantial. Reduced labor costs, minimal material waste, and faster production times make these machines a cost-effective choice.

Creative Freedom

For artists and designers, CNC engraving machines open up a world of possibilities. Complex patterns, intricate lettering, and custom designs are easily achievable, allowing creative visions to come to life.

Applications of CNC Engraving Machines

Jewelry and Accessories

CNC engraving machines are a favorite in the jewelry industry. They create intricate patterns, engrave logos, and personalize items like rings and pendants. Their precision ensures every piece is a masterpiece.

Industrial Components

In manufacturing, precision is non-negotiable. CNC engraving machines produce components with exact measurements, ensuring compatibility and performance. Industries like aerospace and automotive rely heavily on these machines.

Signage and Branding

Engraved signs and branding materials stand out for their durability and elegance. CNC engraving machines create high-quality signage, from intricate logos to large-scale designs, making them a valuable tool for businesses.

Customized Gifts and Trophies

Personalization adds value to gifts and awards. CNC engraving machines allow detailed engravings of names, messages, and designs on items like trophies, plaques, and keepsakes, making them unique and memorable.

Choosing the Right CNC Engraving Machine

Assess Your Material Needs

Different machines specialize in different materials. Determine whether you’ll be engraving metals, plastics, wood, or a combination of materials to find a machine that suits your needs.

Consider the Work Area

The size of the machine’s work area determines the scale of projects you can handle. Choose a machine with a work area that accommodates your typical projects while leaving room for growth.

Prioritize Software Compatibility

Ensure the machine’s software is user-friendly and compatible with your design tools. Advanced software integration allows you to create and modify designs easily, streamlining your workflow.

Check for Support and Training

Invest in a machine from a manufacturer that offers robust support and training. Learning to operate a CNC engraving machine effectively ensures you get the most out of your investment.

Maintenance Tips for CNC Engraving Machines

Keep the Machine Clean

Dust and debris can affect performance. Regularly clean the machine, paying special attention to the spindle, tools, and work area, to ensure consistent results.

Lubricate Moving Parts

Proper lubrication minimizes wear and tear on moving components. Follow the manufacturer’s guidelines for maintaining bearings, rails, and other parts to extend the machine’s lifespan.

Inspect for Wear and Tear

Frequent inspections help identify potential issues before they become major problems. Check for worn tools, loose connections, and other signs of wear to keep your machine running smoothly.

Update Software Regularly

Manufacturers often release software updates to improve functionality and fix bugs. Keeping your software up to date ensures optimal performance and access to the latest features.

The Future of CNC Engraving Machines

Enhanced AI Integration

Artificial intelligence is poised to take CNC engraving to new heights. AI-powered machines will offer predictive maintenance, automated design adjustments, and even greater precision.

Eco-Friendly Innovations

Sustainability is a growing concern in manufacturing. Future CNC engraving machines will likely incorporate energy-efficient features and environmentally friendly materials, aligning with global efforts to reduce carbon footprints.

Portable CNC Solutions

The demand for portable and compact CNC engraving machines is rising. These smaller, more versatile machines will make precision engraving accessible to a wider audience, from hobbyists to small businesses.

Why CNC Engraving Machines Are Worth the Investment

Long-Term Savings

While the upfront cost may seem high, CNC engraving machines save money over time. Reduced labor costs, faster production, and minimal material waste make them a wise investment.

Versatility Across Projects

Whether you’re creating intricate jewelry, producing industrial components, or crafting personalized gifts, CNC engraving machines handle a wide range of applications with ease.

A Competitive Edge

In today’s fast-paced market, staying ahead means embracing innovation. CNC engraving machines give businesses and artists the precision and efficiency needed to outperform competitors.

Unlock New Possibilities with CNC Engraving Machines for Precision

CNC engraving machines are revolutionizing industries by offering unmatched accuracy, efficiency, and versatility. Whether you’re a professional manufacturer or a creative artist, these machines empower you to achieve results that were once impossible. Embrace the future of craftsmanship with CNC engraving machines for precision and take your projects to the next level.