Blog

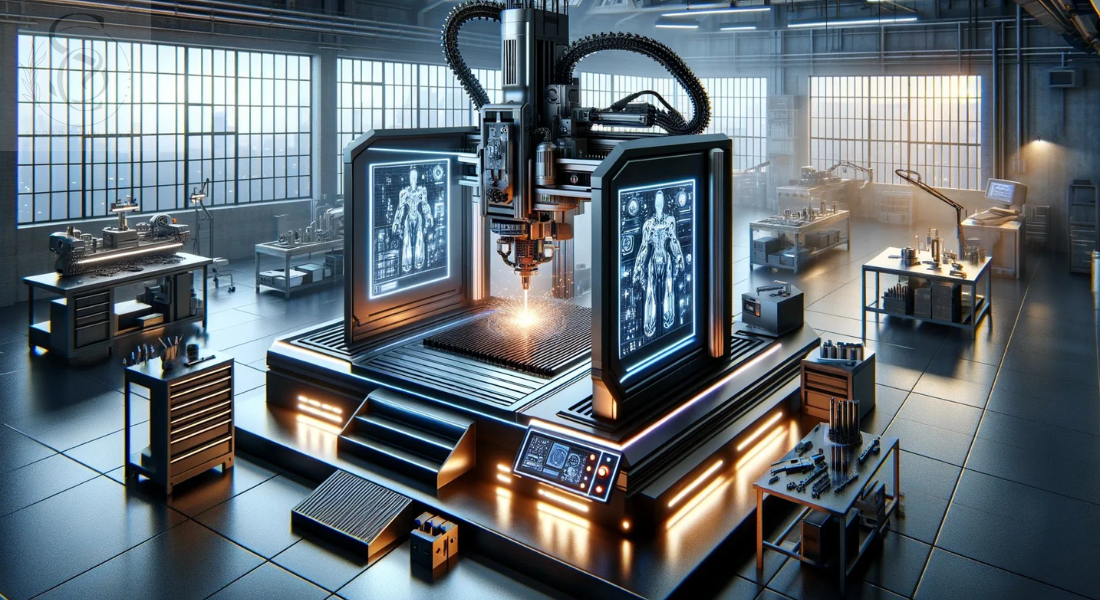

High Tech Milling Machines for Factories Revolutionizing Precision Manufacturing

In today’s fast-paced industrial landscape, high tech milling machines for factories play a critical role. These machines deliver unmatched precision and efficiency, empowering manufacturers to meet complex production demands. By integrating advanced technologies, they are redefining how factories operate, paving the way for innovation and growth.

From crafting intricate components to streamlining mass production, these state-of-the-art machines are the cornerstone of modern manufacturing.

Why Advanced Milling Machines Matter

Elevating Productivity and Accuracy

High-tech machines significantly enhance productivity by performing complex tasks with remarkable speed and precision. Unlike traditional models, they ensure consistent quality, minimizing errors and waste while boosting overall output.

Meeting Industry-Specific Needs

Designed to cater to diverse industries, these machines excel in producing parts for aerospace, automotive, medical devices, and consumer electronics. Their adaptability makes them indispensable for both small-scale operations and large manufacturing plants.

Cutting Costs Without Sacrificing Quality

Investing in high tech milling machines for factories leads to long-term savings. By automating processes, they reduce labor costs and operational downtime while maintaining superior quality standards.

Key Features of High-Tech Milling Machines

Precision Engineering at Its Best

Advanced machines feature computerized controls that allow for intricate machining with tolerances as tight as a fraction of a millimeter. This level of precision is essential for industries demanding flawless components.

Integration of Smart Technology

Modern milling machines incorporate IoT connectivity, real-time monitoring, and AI-driven analytics. These features enable predictive maintenance, optimizing machine performance and reducing unexpected breakdowns.

Versatile Functionality

From vertical and horizontal milling to 5-axis machining, these machines offer unmatched versatility. Their ability to handle diverse materials, including metals, plastics, and composites, ensures they meet a wide range of manufacturing needs.

Energy Efficiency

Sustainability is at the forefront of industrial advancements. Newer models are designed to consume less energy while delivering powerful performance, aligning with eco-friendly manufacturing goals.

Popular Types of Milling Machines

CNC Milling Machines

CNC technology revolutionizes manufacturing by automating processes and ensuring precise, repeatable results. These machines are perfect for factories aiming to scale production without compromising accuracy.

5-Axis Milling Machines

With the ability to machine complex shapes in a single setup, 5-axis machines are a game-changer. Their advanced capabilities allow factories to produce intricate parts with unparalleled efficiency.

Vertical Milling Machines

Vertical mills are versatile and space-efficient, making them ideal for small to medium-sized factories. They excel at machining parts with vertical features, such as slots and grooves.

Horizontal Milling Machines

Known for their robust construction, horizontal mills are perfect for heavy-duty tasks. Their design facilitates faster material removal, making them suitable for large-scale industrial applications.

Choosing the Right Machine for Your Factory

Assessing Production Needs

Understanding your factory’s specific requirements is crucial. Determine the type of parts you’ll produce, the materials you’ll work with, and the level of precision needed. This assessment ensures you choose a machine tailored to your goals.

Budget Considerations

While high-tech machines require a significant investment, the long-term benefits outweigh the costs. Analyze your budget and explore financing options to secure the best equipment for your operations.

Evaluating Software Capabilities

Advanced milling machines rely on sophisticated software for programming and control. Ensure the machine you select offers user-friendly interfaces, robust programming options, and compatibility with your existing systems.

Benefits of Investing in Advanced Milling Machines

Increased Output with Consistent Quality

High-tech machines enable factories to produce more components in less time without compromising quality. Their precision minimizes defects, resulting in higher customer satisfaction.

Enhanced Safety

Automation reduces the need for manual intervention, minimizing risks associated with traditional machining. These machines are equipped with safety features to protect operators and ensure smooth operations.

Future-Proofing Your Factory

As industries evolve, staying competitive requires adopting cutting-edge technology. Investing in high tech milling machines for factories ensures your operations remain efficient and relevant in an ever-changing market.

Real-World Applications

Aerospace Industry

In aerospace manufacturing, precision is non-negotiable. Milling machines produce critical components such as turbine blades and engine parts, meeting stringent safety and performance standards.

Automotive Sector

From engine blocks to transmission components, high-tech machines streamline automotive manufacturing. Their ability to work with lightweight materials like aluminum and carbon fiber supports the industry’s push for fuel-efficient vehicles.

Medical Devices

The medical field relies on milling machines to craft intricate devices like implants and surgical instruments. These machines ensure the highest levels of accuracy and biocompatibility.

Consumer Electronics

Electronics manufacturers use advanced milling machines to produce components for smartphones, laptops, and other devices. Their precision and versatility make them ideal for this fast-paced industry.

Maintenance and Care for Longevity

Regular Inspections

Conducting routine checks ensures your milling machines operate at peak efficiency. Look for signs of wear, misalignment, or unusual noises, and address issues promptly.

Proper Lubrication

Maintaining adequate lubrication prevents excessive wear and tear on moving parts. Use manufacturer-recommended lubricants to ensure optimal performance.

Cleaning and Calibration

Dust and debris can impact machine performance. Regular cleaning and calibration maintain accuracy and extend the lifespan of your equipment.

Future Trends in Milling Technology

Integration of Artificial Intelligence

AI is revolutionizing how factories operate. Advanced algorithms enable machines to learn from production data, optimizing processes and improving efficiency over time.

Modular Machine Designs

Modular designs allow factories to customize machines according to their needs. This flexibility ensures manufacturers can adapt to changing demands without investing in entirely new equipment.

Green Manufacturing

Sustainability is shaping the future of manufacturing. High-tech milling machines now feature energy-efficient designs and use recyclable materials, supporting eco-friendly initiatives.

Remote Monitoring and Control

IoT connectivity enables operators to monitor and control machines from anywhere. This feature enhances productivity and ensures timely interventions when issues arise.

Tips for Maximizing Machine Performance

Invest in Operator Training

Well-trained operators are essential for getting the most out of your milling machines. Regular training sessions keep them updated on new features and best practices.

Use High-Quality Tools

The performance of milling machines depends on the quality of cutting tools used. Invest in durable tools that maintain sharpness and ensure clean cuts.

Monitor Production Metrics

Tracking key performance indicators helps identify areas for improvement. Use this data to fine-tune processes and achieve optimal efficiency.

Conclusion: Embracing Innovation for Success

High-tech milling machines represent the pinnacle of industrial innovation. Their unmatched precision, versatility, and efficiency make them indispensable for modern factories. By investing in these machines, manufacturers unlock new possibilities, driving growth and staying ahead in a competitive landscape.

Whether you’re in aerospace, automotive, or consumer electronics, adopting high tech milling machines for factories ensures your operations remain cutting-edge. Transform your production capabilities and embrace the future of manufacturing today.