Blog

Revolutionizing Manufacturing with High Tech Cutting Machines for Factories

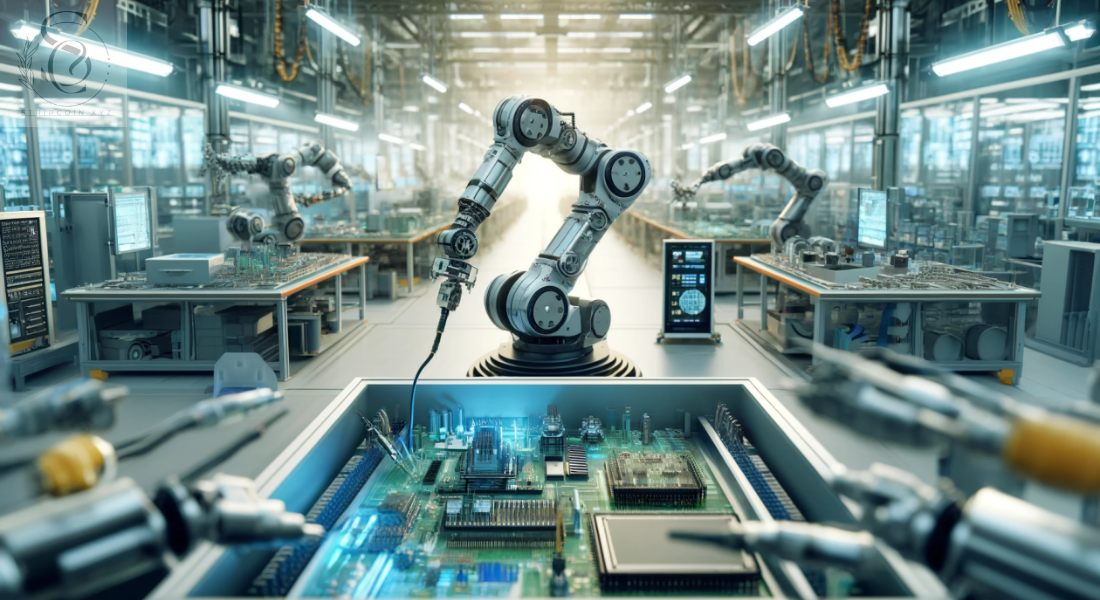

In the fast-paced world of manufacturing, efficiency and precision are key. High tech cutting machines for factories are transforming production processes by combining advanced technology with exceptional accuracy. These machines have become indispensable tools for industries aiming to improve output, reduce waste, and stay competitive.

Why Cutting Machines Are Crucial in Modern Manufacturing

Cutting processes are integral to almost every manufacturing sector, from automotive to aerospace. High tech cutting machines offer the precision and speed needed to meet modern demands. By automating and optimizing these processes, factories can achieve consistent results, reduce errors, and boost productivity.

Precision Redefined with Advanced Cutting Technology

One of the greatest advantages of high tech cutting machines for factories is their unparalleled precision. Using advanced software and laser or waterjet technology, these machines make intricate cuts with minimal material wastage. This precision ensures quality, reduces rework, and saves time.

Speed Meets Efficiency in High Tech Machines

Time is money in manufacturing, and cutting machines designed for factories are built to deliver. With faster cutting speeds and automated features, these machines complete tasks in a fraction of the time it would take with traditional methods. Increased efficiency translates to higher output and quicker delivery times.

Diverse Applications Across Industries

High tech cutting machines for factories cater to various industries, including automotive, aerospace, electronics, and construction. Their versatility makes them suitable for cutting metals, plastics, glass, and even composites. This adaptability ensures they meet the unique needs of different sectors.

Advanced Software for Seamless Integration

Modern cutting machines come equipped with advanced software that integrates seamlessly into factory operations. These programs enable operators to design complex patterns, simulate processes, and monitor real-time performance. Such features streamline production and ensure optimal use of resources.

Eco-Friendly Manufacturing with Cutting Machines

Sustainability is a growing priority in manufacturing. High tech cutting machines reduce waste through precise cuts and optimized material use. Additionally, some models incorporate energy-efficient systems, making them an eco-friendly choice for forward-thinking factories.

Automation: The Backbone of Cutting Machines

Automation is at the heart of high tech cutting machines for factories. With features like automatic loading, unloading, and tool adjustments, these machines minimize manual intervention. Automation not only improves consistency but also enhances worker safety by reducing exposure to hazardous tasks.

Cost Savings Through Advanced Technology

While high tech cutting machines represent a significant investment, they offer long-term cost savings. Reduced material wastage, lower labor costs, and minimized downtime make these machines a cost-effective solution for factories looking to optimize operations.

Enhanced Safety Features Protect Workers

Safety is a top concern in manufacturing, and cutting machines prioritize this with features like enclosed cutting areas, automatic shut-offs, and real-time monitoring. These innovations protect workers while maintaining high levels of productivity.

Laser Cutting: Precision at Its Best

Laser technology has become a cornerstone of high tech cutting machines for factories. Lasers deliver clean, accurate cuts with minimal heat impact, making them ideal for delicate materials. This precision ensures quality while reducing the risk of damage.

Waterjet Cutting: Power and Versatility Combined

For materials like stone, metal, and composites, waterjet cutting offers unmatched versatility. High pressure streams of water mixed with abrasives can slice through even the toughest materials with ease. Factories benefit from the power and adaptability of this technology.

Plasma Cutting for Heavy-Duty Applications

Plasma cutting machines are a favorite in industries working with thick metals. They combine speed and precision, making them perfect for heavy-duty applications. Their robust design ensures reliability and consistent performance in demanding environments.

CNC Integration for Unmatched Accuracy

High tech cutting machines often feature CNC (Computer Numerical Control) systems, enabling precise control over every cut. Operators can program complex designs and ensure repeatable accuracy across large production runs. This technology reduces human error and increases efficiency.

Compact Models for Small Factories

Not every factory has expansive floor space, and compact cutting machines address this issue. These high tech models deliver the same precision and efficiency as their larger counterparts, making them ideal for smaller operations or specialized tasks.

Modular Designs for Scalability

Manufacturers looking to expand can benefit from modular cutting machine designs. These machines grow with production demands, allowing factories to add components or upgrade capabilities over time. Scalability ensures long-term flexibility and cost-effectiveness.

Real-Time Monitoring for Optimal Performance

Real-time data monitoring is a game-changer for factories. High tech cutting machines provide insights into performance, maintenance needs, and material usage. This information helps operators make informed decisions and optimize processes for maximum productivity.

Training and Support Simplify Operation

Even the most advanced machines are user-friendly with proper training. Manufacturers of high tech cutting machines for factories offer comprehensive support, including training sessions, online resources, and customer service. This ensures smooth implementation and effective use.

Popular Brands Delivering Cutting-Edge Solutions

Renowned brands like Bystronic, Trumpf, and Mazak lead the industry with innovative cutting machines. Their products combine advanced technology, durability, and exceptional performance, making them a trusted choice for factories worldwide.

Investing in High Tech Cutting Machines for the Future

Factories investing in high tech cutting machines gain a competitive edge. These machines future-proof operations by enabling automation, improving efficiency, and meeting evolving industry standards. They’re an investment that pays dividends in productivity and profitability.

Industry Testimonials Highlight Success

Factories using high tech cutting machines often report significant improvements in output and quality. Testimonials from industry leaders showcase how these machines transform production processes, reduce costs, and meet customer demands more effectively.

Customization Meets Industry-Specific Needs

Every factory has unique requirements, and cutting machines can be customized to meet them. From specialized tools to tailored software, manufacturers offer solutions that align perfectly with specific production goals.

Exploring the Future of Cutting Technology

The future of cutting machines lies in further integration with AI and IoT (Internet of Things). Predictive maintenance, self-learning capabilities, and advanced automation promise even greater efficiency and precision in the years to come.

Final Thoughts: Revolutionize Production with Cutting Machines

High tech cutting machines for factories represent the pinnacle of modern manufacturing. With features like automation, precision, and versatility, these machines transform how factories operate. Investing in cutting-edge technology ensures businesses stay ahead of the competition, delivering superior products while optimizing costs. Upgrade your factory today and embrace the future of manufacturing innovation.